Product Description

Drader Injectiweld

Delivers Quality Welds

Rental Units Available!

Drader Injectiweld uses heat from the welding tip to pre-plasticize the welding surface of the thermoplastic. Molten plastic is immediately injected sub-surfacely under pressure, into the weld area to fuse the plastic together and form a sound weld. Since the orifice in the weld tip is submerged, surface preparation is not necessary and virtually no oxidation takes place during the welding process. The result is an efficient quality weld.

Fabricating: Injectiweld is easily adapted into production and assembly applications. The one-hand operation of the Injectiweld allows the user to manipulate the parts to be welded with the other hand. The welder can then free form product for faster turnover and production.

Prototyping: Products can be designed and developed using the Injectiweld. The strong welds achieved using the Injectiweld lets welded prototypes be used in real life tests. The Injectiweld is capable of producing welds as small as 1.5 mm for inconspicuous welds and up to 15 mm for added weld strength.

Repair: The combination of heat and pressure from the Injectiweld produces quality welds on previously unrepairable parts, allowing them to be fixed and put back into service. The Injectiweld is utilized in various industries such as: materials handling, lining, transportation, safety supply, and custom repair.

Demonstration of Injectiweld repairing plastic holes applications.

Plastic puncture repair by Injectiweld tool video demonstration

Injectiweld repairing punctured plastic

Materials that can be welded with the Injectiweld

The following table lists materials commonly welded with the Injectiweld. While many thermoplastics are weldable with the Injectiweld, some resins have not been tested extensively and therefore do not appear on the following list. Note the weld temperatures are specific to the Injectiweld system.

| Material |

Description |

Injectiweld Weld Temp in °C |

Injectiweld Weld Temp in °F |

| HDPE |

High Density Polyethylene |

265 |

510 |

| LLDPE |

Linear Low Density Polyethylene |

265 |

510 |

| HMWPE |

High Molecular Weight Polyethylene |

280 |

536 |

| PP |

Polypropylene |

280 |

530 |

| ABS* |

Acrylnitrile Butadiene Styrene |

265 |

510 |

| PS |

Polystyrenes |

255 |

490 |

| PVDF* |

Poly vinyl difouride |

300 |

572 |

| PA* |

Polyamide 6 (nylon) |

300 |

570 |

| PC* |

Polycarbonate |

300 |

570 |

| PU |

Polyurethane (thermoplastic) |

300 |

570 |

| Santoprene |

TPE Thermoplastic Elastomer |

280 |

530 |

| X-Linked PE* |

Cross-linked PE (See Special Treatment) |

300 |

572 |

* Some materials are hygroscopic (i.e. they absorb moisture from the surrounding environment). When

hygroscopic welding rod melts, the moisture boils. It will show up as a ‘bubbly’ appearance on the weld. To

avoid this, dry the welding rod before welding. Drying times vary depending on the drying equipment, the

amount of welding rod, its moisture level, and outside humidity. See Snap on Preheater flyer above in

Video and Docs tab or use an inexpensive food dehydrator.

Model W30000 Injectiweld

Includes:

- W30000 Injectiweld

- Barrel Washer

- 3/16" Fillet Weld Tip

- Repair Tip

- Tip Nut Wrench

- Tip Nut

- Scraping Blade

- Stick Scraper

- Air Filter Assembly

- Screwdriver

- Extra Fuse

- Heat Transfer Compound

- Quick Manual (not shown)

- Carrying Case (not shown)

Other Tips:

- T20007 Blank Tips 5¼" length, semi-finish tips used to design your own welding tip.

- T20008 Prototyping Tip 2" long. Used for prototyping and repairs where small welds are required.

- T20010 Repair Tip 1¼" long. Used for prototyping and repairs where small welds are required.

- T20003 Bull Nose Tip 1¼" long. Used for repairing blow holes in rotomolded parts. 1/2" diameter.

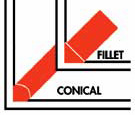

- T20001 Fillet Weld Tip 3/16" fillet weld tip used for butt and right angle welds. Part of original welding kit.

- T20004 Fillet Weld Tip 1/4" fillet weld tip used for butt and right angle welds.

- T20005 Fillet Weld Tip 3/8" fillet weld tip used for butt and right angle welds.

- T20011 Fillet Weld Tips ½" fillet weld tip used for butt and right angle welds.

- T20009 Ribbon Weld Tip Used for welding thermoplastic belting or sealing flat joints. 5/8" wide bead.

Stick Beveler/Scraper

Cleaning and beveling edge of repair with stick beveler |

Tip preheats surface as welding bead is applied |

After welding, excess is trimmed |

Straight Scraper Blade finishes weld surface |

Weight: 5.95 lbs

Temperature Range: 220°C to 310°C (428°F to 590°F)

Fuse Rating: 120 Volt Model = One 4 amp Fast-Blow Fuse

Fuse Rating: 240 Volt Model = Two 4 amp Fast-Blow Fuses

Power: 120 VAC, 60 Hz, 400 W or 240 VAC, 50 Hz, 400 W

Air Pressure: 4 cfm @ 100 psi., clean and filtered

Plastic Rod: 5/32 inch diameter (or 4mm diameter). We offer welding rod. Click

here.

Butt Weld |

Conical Weld |

Repair Weld |

Spot Weld |

Materials that cannot be welded with the Injectiweld:

Thermoset plastics are not weldable because they do not melt when heat is applied to them. Examples: F.R.P. (Fiberglass), Bakelite, Epoxies, Phenolics, Melamine, etc.

PVC-U/ PVC-P – PolyVinylChloride (Rigid / Flexible). The lowest temperature setting of the Injectiweld is too high for PVC-U or PVC-P. The material will burn inside the welder’s barrel. This will release chlorine gas, which is harmful to the operator’s health and will damage the aluminum parts of the welder.

PMMA – PolyMethyl MethAcrylate. Using this material inside the Injectiweld may cause the Piston Rod to become stuck. When PMMA is sheared, it exhibits very sharp edges around the circumference of the breakage. These sharp edges may prohibit the Piston Rod from moving backwards.

PFA – PerFluoro Alkoxy The weld temperature for this material exceeds the maximum temperature setting.