Product Description

Vortex Tube Kits

What is a Vortex Tube?

A low cost, reliable, maintenance-free solution to a variety of industrial spot cooling problems. Using an ordinary supply of compressed air as a power source, vortex tubes create two streams of air, one hot and one cold, with no moving parts. Vortex tubes can produce:

- Temperatures from -50° to 260°F (-46° to 127°C)

- Flow rates from 1 to 150 SCFM (28 to 4248 SLPM)

- Refrigeration up to 10,200 Btu/hr. (2571 Kcal/hr.)

Temperatures, flows and refrigeration are adjustable over a wide range using the control valve on the hot end exhaust.

Applications

- Cooling electronic controls

- Cooling machining operations

- Cooling CCTV cameras

- Setting hot melts

- Cooling soldered parts

- Cooling gas samples

- Electronic component cooling

- Cooling heat seals

- Cooling environmental chambers

Advantages

- No moving parts

- No electricity or chemicals

- Small, lightweight

- Low cost

- Maintenance free

- Instant cool air

- Durable stainless steel

- Adjustable temperature

- Interchangable generators

Why Vortex Tubes?

|

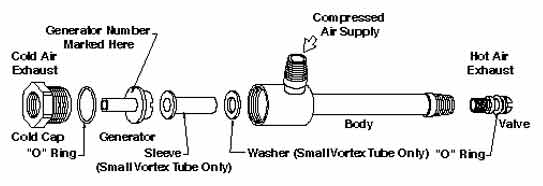

Vortex Tubes are constructed of stainless steel. The wear resistance of stainless steel, as well as its resistance to corrosion and oxidation, assures that Vortex Tubes will provide years of reliable, maintenance-free operation.

|

A Model 3215 Vortex Tube cools a die on a medical tube forming machine. |

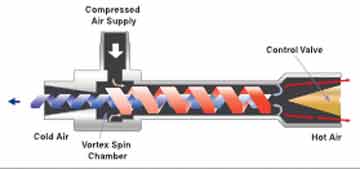

How a Vortex Tube Works

Compressed air, normally 80-100 PSlG (5.5 - 6.9 BAR), is ejected tangentially through a generator into the vortex spin chamber. At up to 1,000,000 RPM, this air stream revolves toward the hot end where some escapes through the control valve. The remaining air, still spinning, is forced back through the center of this outer vortex. The inner stream gives off kinetic energy in the form of heat to the outer stream and exits the vortex tube as cold air. The outer stream exits the opposite end as hot air.

Controlling Temperature and Flow in a Vortex Tube

Cold airflow and temperature are easily controlled by adjusting the slotted valve in the hot air outlet.

Opening the valve reduces the cold airflow and the cold air temperature. Closing the valve increases the cold airflow and the cold air temperature. The percentage of air directed to the cold outlet of the vortex tube is called the "cold fraction". In most applications, a cold fraction of 80% produces a combination of cold flow rate and temperature drop that maximizes refrigeration, or Btu/hr. (Kcal/hr.) output of a vortex tube. While low cold fractions (less than 50%) produce lowest temperatures, cold airflow rate is sacrificed to achieve them.

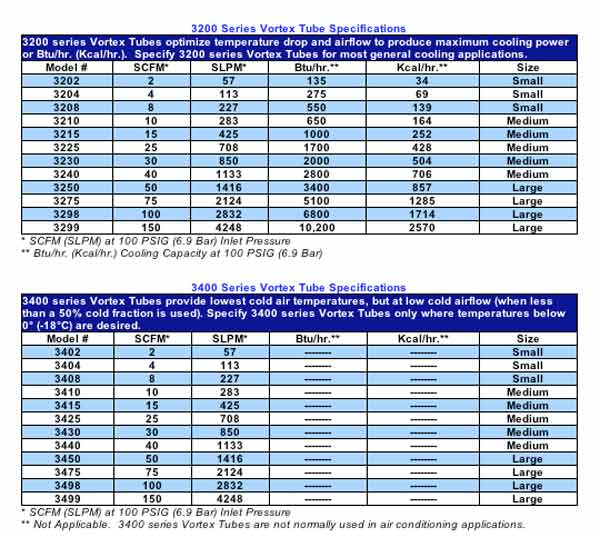

Most industrial applications, i.e., process cooling, part cooling, chamber cooling, require maximum refrigeration and utilize the 3200 series Vortex Tube. Certain "cryogenic" applications, i.e., cooling lab samples, circuit testing, are best served by the 3400 series Vortex Tube.

Setting a vortex tube is easy. Simply insert a thermometer in the cold air exhaust and set the temperature by adjusting the valve at the hot end. Maximum refrigeration (80% cold fraction) is achieved when cold air temperature is 50° F (28 ° C) below compressed air temperature.

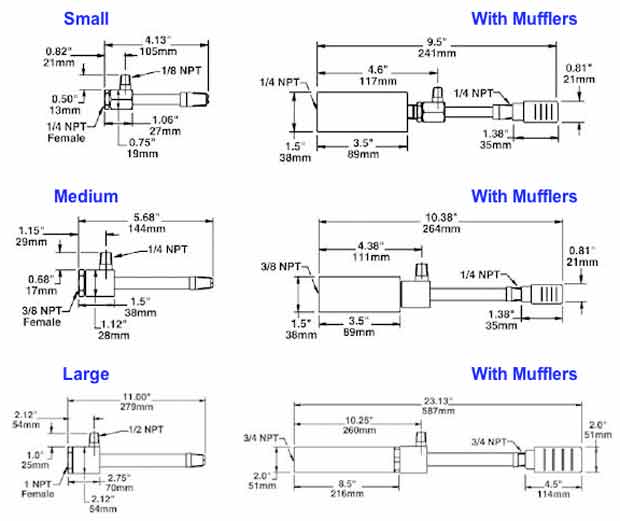

Selecting the Right Vortex Tube

Vortex Tubes are available in three sizes. Each size can produce a number of flow rates, as determined by a small internal part called a generator. If Btu/hr. (Kcal/hr.) requirements, or flow and temperature requirements are known, simply select the appropriate vortex tube according to the specification information shown below or the performance charts shown on the following page. Keep in mind that the vortex generators are interchangeable. If, for example, a Model 3215 Vortex Tube does not provide sufficient cooling, you need only change generators within the vortex tube to upgrade the flow rate from 15 to 25, 30 or 40 SCFM (425 to 708, 850 or 1133 SLPM). Generator part numbers are shown in the "Accessories" listing of the "Models" section

Vortex Tube Specifications

3200 series Vortex Tubes optimize temperature drop and airflow to

produce maximum cooling power or Btu/hr. (Kcal/hr.). Specify 3200 series Vortex Tubes for most general cooling applications.

3400 series Vortex Tubes provide

lowest cold air temperatures, but at low cold airflow (when less than a 50% cold fraction is used). Specify 3400 series Vortex Tubes only where temperatures below 0°F (-18° C) are desired.

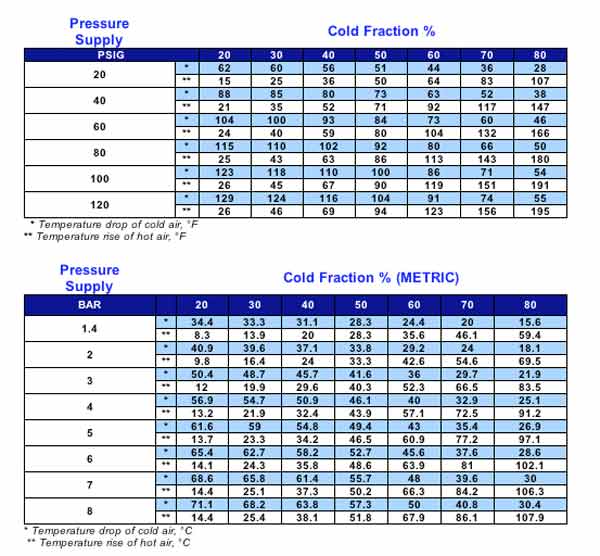

Vortex Tube Performance

The Vortex Tube Performance Charts below give approximate temperature drops (and rises) from inlet air temperature produced by a vortex tube set at each cold fraction. Assuming no fluctuation of inlet temperature or pressure, a vortex tube will reliably maintain temperature within +/- 1° F.

Back Pressure:

The performance of a vortex tube deteriorates with back pressure on the cold air exhaust. Low back pressure, up to 2 PSlG (.1 BAR), will not change performance. 5 PSlG (.3 BAR) will change performance by approximately 5° F (2.8° C).

Filtration:

The use of clean air is essential, and filtration of 25 microns or less is recommended. Filters contain a five micron element and are properly sized for flow.

Inlet Air Temperature:

A vortex tube provides a temperature drop from supply air temperature (see Performance Charts above). Elevated inlet temperatures will produce a corresponding rise in cold air temperatures.

Noise Muffling:

Mufflers for both the hot and cold air discharge are available. Normally, muffling is not required if the cold air is ducted.

Regulation:

For best performance, use line pressures of 80 to 110 PSlG (5.5 to 7.6 BAR). Maximum pressure rating is 250 PSlG (17.2 BAR), minimum 20 PSlG (1.4 BAR).

Products Using Vortex Tubes

Over the years, the basic vortex tube has been used in virtually hundreds of industrial cooling applications. A few have become so popular as to warrant the development of an "applied product" designed to suit the specific application.

Adjustable Spot Cooler: With the turn of a knob, the Adjustable Spot Cooler provides a precise temperature setting to -30° F (-34° C).

Mini Cooler: The Mini Cooler prevents burning, melting and heat related breakage with 20°F (-7° C) cold air. It is ideal for cooling small tools, blades, needles and lenses.

Component Cooler: Eliminate harmful CFCs! Cold test electronic components with -40° air.

Cold Gun Aircoolant System: Replaces messy mist systems, cools dry machining operations with clean, cold air.

Cabinet Coolers: Cool and purge electronic enclosures. Eliminate malfunctions caused by overheating or dirt infiltration.

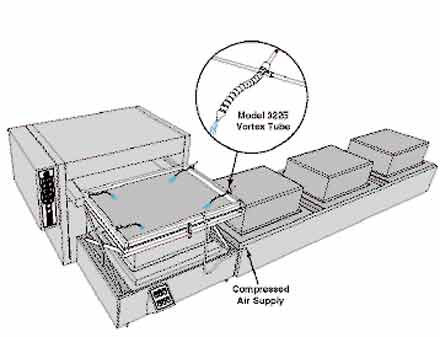

Cooling Vacuum Formed Parts

The Problem:

The Problem: A manufacturer of major appliances vacuum forms the plastic interior shell of refrigerators. The deep draw of the plastic and complex geometry left the four corners unacceptably thin. The corners would tear during assembly or bulge when insulation was inserted between the shell and exterior housing, resulting in a high rejection rate.

The Solution: (4) Model 3225 Vortex Tubes were positioned to cool the critical corner areas just prior to forming the plastic sheet. By cooling these areas, less stretching of the plastic occurred which resulted in thicker corners.

Comment: Rejected parts become very costly, especially when expensive materials and slow process times are involved. The cold air from the vortex tube is just the solution for big problems like this one. It can supply "instant" cold air down to minus 50° F (-46° C) from an ordinary compressed air supply. Along with cooling other vacuum formed parts such as spas, bathtubs, tote pans and waste cans, it is ideal for cooling hot melts, ultrasonic welders, environmental chambers, etc.

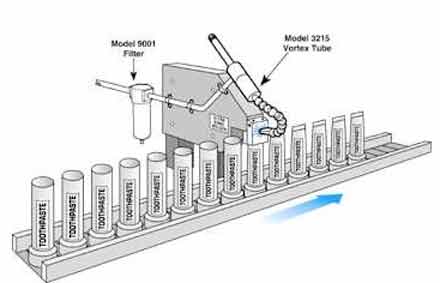

Cooling An Ultrasonic Weld

The Problem:

The Problem: A manufacturer of toothpaste seals the ends of plastic tubes with an ultrasonic welder prior to filling. As heat built up at the sealing jaw of the welder, release of the tubes was delayed. Tubes that were too hot would not seal resulting in a high rate of rejection.

The Solution: A Model 3215 Vortex Tube was used to direct cold air at the jaw of the welder. The cooling was transferred through the metal jaw to the tube seam while in the clamped position. Process time was reduced and rejected tubes were eliminated.

Comment: It amazes most people that the cooling from a small vortex tube can dramatically improve quality and throughput. The vortex tube is the low cost solution for cooling parts, chambers, heat seals and various processes. They're easy to use, can be adjusted to produce cold air down to -50° F (-46° C) and have no moving parts to wear out.

Cooling Kits include a vortex tube, all generators, cold muffler, fitting, tubing and clips to duct cold air, filter separator.

Prices FOB OH.