Welding Plastic

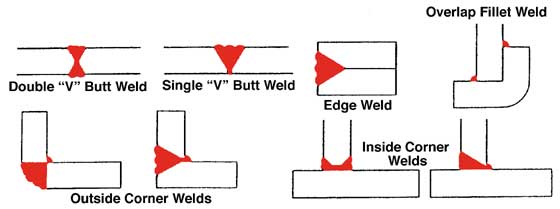

Most Common Types of Welds

Most Thermoplastic material that can be softened or shaped by heat can be welded with a hot air welder. This lightweight, hand-held equipment makes it easy for even inexperienced users to develop the “feel” for welding plastic— doing it economically and with speed after only a few hours of study and practice.

Whether fabricating thermoplastic stock or repairing various types of plastic parts, hot air welding is usually performed on plastics with a thickness of 1/16" or more. The bonds achieved, depending on the type of weld, are generally as strong (90% or more) than the original material.

Selection of Rods

Select a welding rod of the same material as the base material. For the purpose of matching the welding rod material to the base material, use this guideline: Look for labels on the base material and on the package in which the rods or strips were delivered.

Welding Rod Sizing

For maximum welding economy, select a rod diameter size close to the thickness size of the base material. For base material thickness greater than 3/16", more than one rod will be necessary. Example: to weld, the bevelled area between two base material sheets of 1/4" thickness, three 5/32" rods will be required. Rods are available in 1/8", 5/32", 3/16" diameter.

| Base Material Thickness |

Welding Rod Size |

| 1/16" |

1/8" Diameter |

| 1/8" |

1/8" Diameter |

| 3/16" |

3/16" Diameter |

| 1/4" |

3 rods of 5/32" Diameter |

| For thicknesses greater than 1/4" use multibeads to fill |

5/32" or 3/16" Diameter |

Welding Video

Our new Industrial Welding Video is a detailed instructional demonstration on how to weld pipe/fittings, ducting, and tanks. This video demonstrates the use of our tacking tip, round tip, and high speed production tips and for welders on pages (15 minute color video).

$19.95 FOB FL

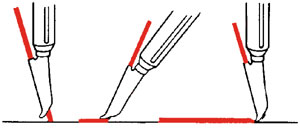

High Speed Welding

Either the rod or strip is fed through a special high speed welding tip containing a feeding channel which makes it unnecessary for the welder to hold the rod or strip in hand while welding is performed.

A person performing high speed welding, moving the welder at proper speed, can join 2 feet of Polyvinyl Chloride, Polyethylene, or Polypropylene in a minute. Seams, joints, or repair areas can be as strong or stronger than the original or base material welded (90% or better, depending on the type of weld applied).

When performing high speed welding, remove welding rod from the feeder tube immediately when the weld is completed. Always clean the rod feeder tube with the feeder tube brush before and after completion of the weld.