Product Description

Injectiweld Rental per week

Weekly rental of Drader Injectiweld, $445 per week.

Weekly rental of Drader Injectiweld, $445 per week.

Shipping not included. Welding rod not included.

The rental period does not start until you have both the welder and the welding rod in your possession. Up to 3 weeks of rental fees can be deducted from the purchase price if the customer decide to order a new Injectiweld within 4 weeks of the end of the rental period. The rental period starts the day after receipt of the shipment. If the customer wants to extend the rental period, Abbeon must be notified before the weekly rental period ends. The customer is responsible for both the delivery and return shipping costs. The equipment must be returned in good working condition, similar to the way it was received, and in the original boxes. Damage to the equipment during shipment must be reported immediately upon receipt. If the equipment is returned damaged, the customer will be responsible for repair costs.

Rental includes the 3/16" Fillet Weld Tip and Repair Tip. Additional tips must be purchased separately.

The Injectiweld requires a 120V 90-100 psi compressed air source (not included).

Rental kit includes:

- W30000 Injectiweld

- Barrel Washer

- 3/16" Fillet Weld Tip

- Repair Tip

- Tip Nut Wrench

- Tip Nut

- Scraping Blade

- Stick Scraper

- Air Filter Assembly

- Screwdriver

- Extra Fuse

- Heat Transfer Compound

- Quick Manual (not shown in photo above)

- Carrying Case (not shown in photo above)

Materials that can be welded with the Injectiweld

The following table lists materials commonly welded with the Injectiweld. While many thermoplastics are weldable with the Injectiweld, some resins have not been tested extensively and therefore do not appear on the following list. Note the weld temperatures are specific to the Injectiweld system.

| Material |

Description |

Injectiweld Weld Temp in °C |

Injectiweld Weld Temp in °F |

| HDPE |

High Density Polyethylene |

265 |

510 |

| LLDPE |

Linear Low Density Polyethylene |

265 |

510 |

| HMWPE |

High Molecular Weight Polyethylene |

280 |

536 |

| PP |

Polypropylene |

280 |

530 |

| ABS* |

Acrylnitrile Butadiene Styrene |

265 |

510 |

| PS |

Polystyrenes |

255 |

490 |

| PVDF* |

Poly vinyl difouride |

300 |

572 |

| PA* |

Polyamide 6 (nylon) |

300 |

570 |

| PC* |

Polycarbonate |

300 |

570 |

| PU |

Polyurethane (thermoplastic) |

300 |

570 |

| Santoprene |

TPE Thermoplastic Elastomer |

280 |

530 |

| X-Linked PE* |

Cross-linked PE (See Special Treatment) |

300 |

572 |

Cleaning and beveling edge of repair with stick beveler |

Tip preheats surface as welding bead is applied |

After welding, excess is trimmed |

Straight Scraper Blade finishes weld surface |

Weight: 5.95 lbs

Temperature Range: 220°C to 310°C (428°F to 590°F)

Fuse Rating: 120 Volt Model = One 4 amp Fast-Blow Fuse

Fuse Rating: 240 Volt Model = Two 4 amp Fast-Blow Fuses

Power: 120 VAC, 60 Hz, 400 W or 240 VAC, 50 Hz, 400 W

Air Pressure: 4 cfm @ 100 psi., clean and filtered

Plastic Rod: 5/32" (or 4mm diameter)

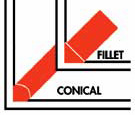

Butt Weld |

Conical Weld |

Repair Weld |

Spot Weld |

Materials that cannot be welded with the Injectiweld

Thermoset plastics are not weldable because they do not melt when heat is applied to them. Examples: F.R.P. (Fiberglass), Bakelite, Epoxies, Phenolics, Melamine, etc…

PVC-U/ PVC-P – PolyVinylChloride (Rigid / Flexible). The lowest temperature setting of the Injectiweld is too high for PVC-U or PVC-P. The material will burn inside the welder’s barrel. This will release chlorine gas, which is harmful to the operator’s health and will damage the aluminum parts of the welder.

PMMA – PolyMethyl MethAcrylate. Using this material inside the Injectiweld may cause the Piston Rod to become stuck. When PMMA is sheared, it exhibits very sharp edges around the circumference of the breakage. These sharp edges may prohibit the Piston Rod from moving backwards.

PFA – PerFluoro Alkoxy The weld temperature for this material exceeds the maximum temperature setting.